More on the transmission. I was able to locate shim stock to finish the assembly of the constant motion shaft. Turns out that

you have to ask for "Shim Stock in a Can". Really. The machinists have it and I bought a small sheet of 0.004 stock and using a scissors and an x-acto knife, cut three washers and ta da-the constant motion shaft is done. So the box itself is closed up. I rebuilt the top assembly from pieces lying around and although it is Moss chunky, it seems to be working fine.

The thing that sets off the proper JH style box is the tail assembly that encloses the longer mainshaft. There is a yet- to- be- installed rear housing that is having some repair welding completed. That final housing contains the rear seal, the speedometer gearing, and the yoke to mount to the driveshaft. I need to order a new rubber bushing for the gearshift- currently it rotates as one moves through the gears. Also, the top cover needs new bolts (they are a British thread style- approximately 5/16" x 21 pitch- try finding those in your local Ace Hardware) and the bellhousing bolts need new locktabs.

The jack is painted.

The clutch and brake pedals are primed.

Other news- the crankshaft that I just bought is bent 0.003". Bouchers is going to try to straighten it next week. Believe it or not, they have this big-a__ machine that has a hook that grabs the crank and pulls it into shape. It cannot be turned again as it is already cut to the max over at 0.030" on the mains. Joy. I am optomistic that it will straighten. Pistons at 9:1 CR and 0.060" over are currently being fabricated.

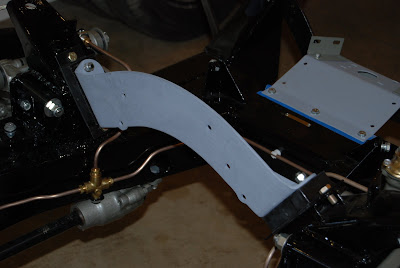

. These first shots are before and after on the brackets that hold the windshield wiper posts. They fit immediately behind the dash and are in good shape. Just needed cleaning and painting. The smaller brackets are the behind the dash supports for the chrome passanger grab bar.

. These first shots are before and after on the brackets that hold the windshield wiper posts. They fit immediately behind the dash and are in good shape. Just needed cleaning and painting. The smaller brackets are the behind the dash supports for the chrome passanger grab bar.