A couple things going on in the shop today. The car came with side curtain frames. Unfortunately, the one for the left was the proper short version for this early 120 and the other side was for a later version. So using the left for a pattern, I cut and slightly reshaped the right to match. Since it was longer, small pieces were cut out and the frames and then it was rewelded.

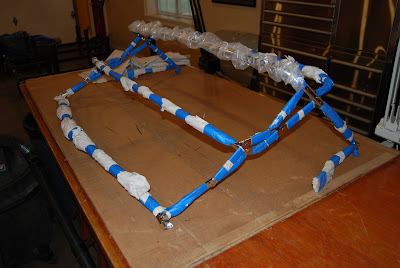

The other thing going on was that I got the rivets for the latches for the top bows and peened them into position. Its all pretty stiff right now but I suspect that it will loosen up just fine when it eventually gets some use. There are a number of pieces that are unique to the early version short top that are not available as replacement parts by the domestic parts suppliers: the top bow attachment bolts and the spacer washers. Later version parts don't fit so I'll have to see if mine can be reconditioned and chromed.